专业制造商

质量保证

及时交货

贴心售后

COMPANY INTRODUCTION

专业的流体解决方案提供商

莱州市东升阀门有限公司(以下简称公司)成立于2002年,位于齐鲁文化底蕴深厚的山东省莱州市,是一家集制造、销售和设计研发于一体的工贸出口型企业。

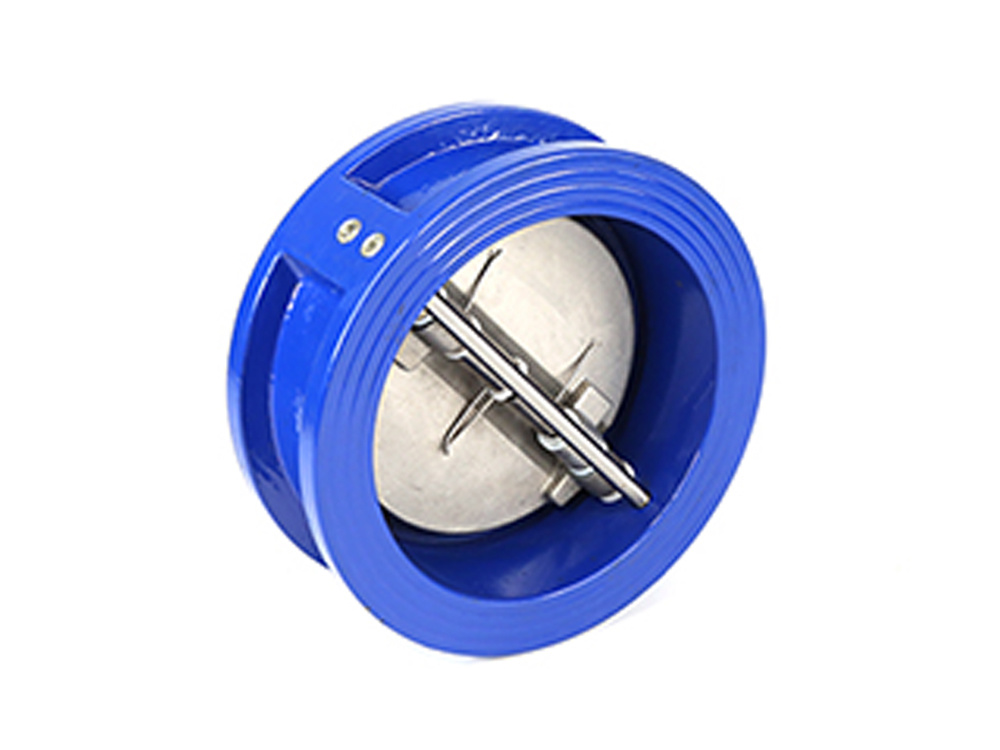

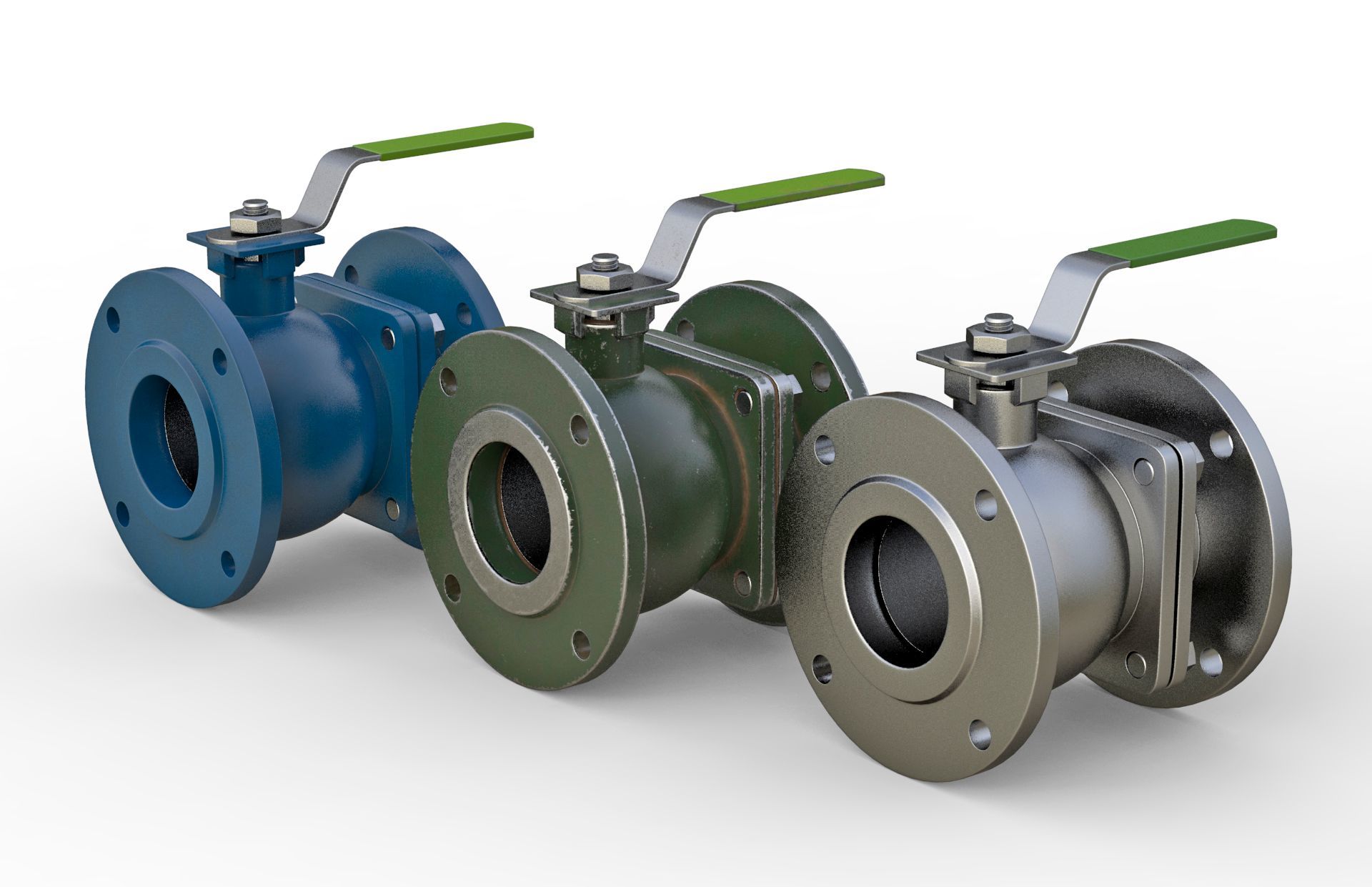

公司主要制造止回阀、隔膜阀、球阀和蝶阀等产品,产品广泛应用于石油、化工、矿业及供排水、净化水、蒸汽、流体食品、酸碱溶液等管路设备系统,以高端阀门产品为重点,主销欧美市场。

20

+

产品型号及规格

500

+

产品型号及规格

70

+

产品销售国家和地区

NEWS INFORMATION

聚焦资讯新闻

GET IN TOUCH WITH US!

有问题?联系我们