Rising Stem Diaphragm Valve(Blue)

Product Video

Product Description

Diaphragm Valves have two kinds of types, wire and full flow, which use a ‘pinching’ method to stop the valve flow using a flexible diaphragm.These types of valves are generally not suited for very high-temperature fluids and are mainly used on liquid systems.

We’ll make every effort and hard work to be superb and excellent, and speed up our steps for standing inside the rank of international top-grade and high-tech enterprises for New Style China DN300 Cast Iron Flange Rising Stem Diaphragm Valve, Welcome to visit us at any time to establish long-term business. Please feel free to contact us by email info@lzds.cn or phone/WhatsApp +86 18561878609.

New Style China GG25 Diaphragm Valve, GGG40 Diaphragm Valve, Now we have gained a lot of recognition among customers spread all across the world. They trust us and always give us reorder.

Advantages of Diaphragm Valve

- Can be used as on-off and throttling service valves.

- Offer good chemical resistance due to a variety of linings available.

- Stem leakage is eliminated.

- Provides bubble-tight service.

- Does not have pockets to trap solids, slurries, and other impurities. It is suitable for slurries and viscous fluids.

- These valves are particularly suitable for hazardous chemicals and radioactive fluids.

- These valves do not permit contamination of flow medium, thus they are used extensively in food processing, pharmaceutical, brewing, and other applications which cannot tolerate any contamination.

Typical Application of Diaphragm Valves

- Clean or dirty water and air service applications

- Demineralized water systems

- Corrosive applications

- Radwaste systems in nuclear facilities

- Vacuum service

- Food processing, pharmaceutical, and brewing systems

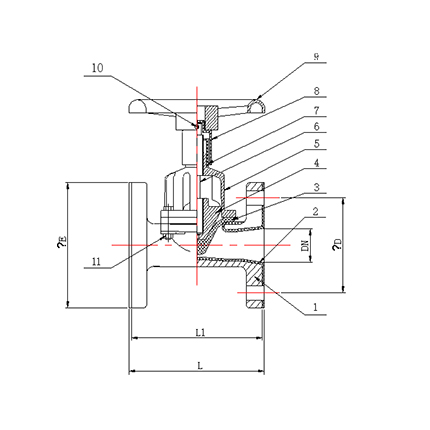

Product parameter

| NO. | Part | Material |

| 1 | Body | GG25 |

| 2 | Lining | NR |

| 3 | Diaphragm | NR |

| 4 | Disc | GG25 |

| 5 | Bonnet | GG25 |

| 6 | Shaft | Steel |

| 7 | Sleeve | ABS |

| 8 | Sleeve | ABS |

| 9 | Handle | GGG40 |

| 10 | Pin | Steel |

| 11 | Bolt | Steel |

| DN(mm) | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | |

| L (mm) | 194 | 216 | 258 | 309 | 362 | 412 | 527 | 640 | 755 | |

| L1(mm) | 188 | 222 | 252 | 301 | 354 | 404 | 517 | 630 | 745 | |

| ΦE (mm) | 165 | 185 | 198 | 220 | 250 | 283 | 335 | 395 | 445 | |

| ΦD (mm)(EN1092-2) | PN10 | 125 | 145 | 160 | 180 | 210 | 240 | 295 | 350 | 400 |

| PN16 | 355 | 410 | ||||||||

Product Show